Collaborative Robots – The Time To Adopt Is Now

Overview

While human workers handle more complex tasks on the floor, robots have always taken dangerous and repetitive tasks. With these two together in harmonious collaboration, many of the challenges in manufacturing can be eliminated. That is what cobots bring to the table.

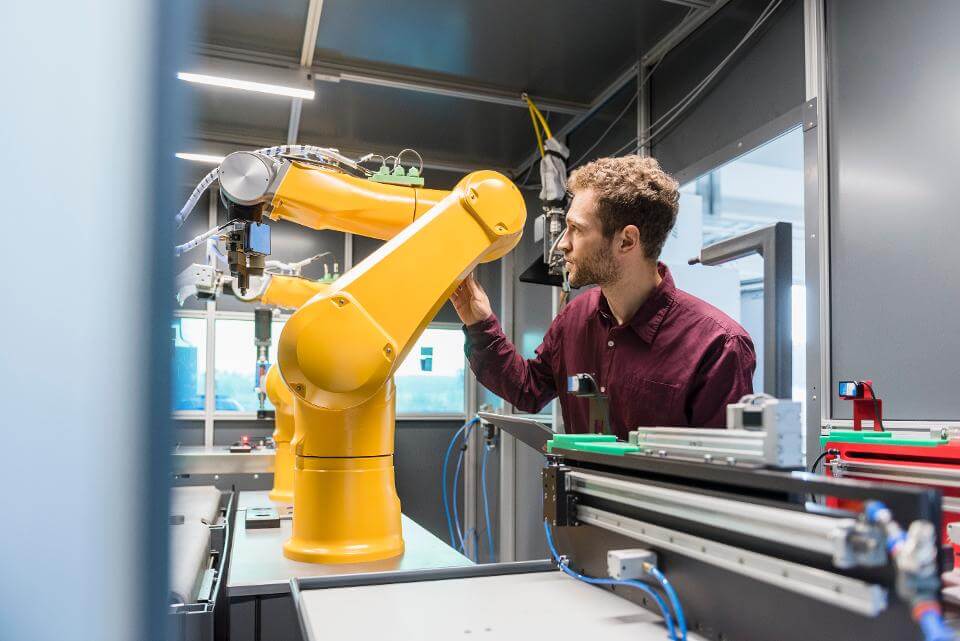

Collaborative robots, or cobots, have been a game-changer in the past decade due to their ability to work side-by-side with humans. Thanks to increased safety, dexterity, and ease of implementation, they are the new favorites in smart factories.

What Are Cobots

Cobots are robots designed to interact and collaborate with humans. They can work in the same space and co-operate concurrently or sequentially on the same project.

To achieve this end, collaborative robots have significant features that differentiate them from traditional robots.

How Are Cobots Different From Traditional Industrial Robots

- Safety – Cobots have to undergo mandatory risk assessment as to their design, operation, and potential industrial applications. That is because they work in proximity to humans.

- Collaboration – Collaborative robots work hand in hand with their human counterparts, hence the name. They can work on a project at the same time or in sequence, but always in the same workspace. Traditional robots work in a separate environment with indirect guidance and control.

- Implementation – Cobots are much easier to set up and get running. With most of this, an implementation time of a few hours to a few days is typical, as opposed to weeks with traditional robots.

- Versatility – Cobots are applicable in a vast array of processes. You can adapt them to suit almost every stage on the production line, with the main limitation being in their power limitations. Other industrial robots tend to have highly specific tasks.

Benefits Of Cobots

- Setup and implementation are easy and fast. Cobots have almost turn-key setup capabilities.

- Adaptable to many tasks. Thanks to their versatility and flexibility, cobots can perform many different types of functions.

- Low costs of implementation as they don’t have as many safety considerations. Cobots are ready-to-use robots without indirect implementation costs.

- Safe and collaborative. Factory managers can capitalize on the unique strengths of both human and machine assets on the floor to achieve maximum productivity.

- With up to 7-degrees of flexibility, most cobots offer almost similar functionality as a human arm.

What We Offer

At Labh Group, we have the most advanced factory automation solutions. Introducing LaBot: Labh Robot, the most advanced cobot applicable in almost any environment.

Labh Group remains at the forefront of Industry 4.0 because we believe in turning innovation into value with break-through technology. We create new opportunities for all our clients and deliver unrivaled ROI on all implementations.

Labh Group is your partner of choice for collaborative smart factories. Let us, with your help, blaze the way to a brighter age of smart factories in the vision of Industry 4.0.

Liked this article? Share it on:

Featured insights and blogs

The secret to cultivating operational excellence

A big focus area across industries is continuous improvement. Companies are under extreme pressure to perform but operational complexities hinder from realising intended outcome.

What makes a factory smart

The smart factory is the factory of the future. It is one where processes are automated, interconnected, and continually reacting towards improving production systems and processes. In simple terms, it is ‘intelligent manufacturing.’

6 key benefits of industry 4.0

Industry 4.0 is the transformation of traditional industrial and manufacturing platforms into automated and interconnected systems capable of continuous autonomous improvement and automation.

Adopting cobots - Collaborative robots

The use of collaborative robots (cobots), is expected to grow at astonishing rates in the next few years. They have been a game-changer in the past decade due to their ability to work side-by-side with humans.

Our experts are always available to answer all your questions. Feel free to write to us and get your queries answered.

About Labh Group

Labh Group is a leading engineering, technology, consulting and manufacturing conglomerate, working closely with diversified industries spanning across food processing, agriculture, plastics, chemicals, healthcare, packaging and other industries and business sectors offering complete turn-key solutions including advanced engineering, Industry 4.0 solutions, expert technical and management consultancy and Digital Transformation. From the most demanding to the most distant customers across the globe, we empower them for rewriting their future with our depths of knowledge, unique ideas, technical expertise, creative solutions and enduring results, all at the most optimal costs, right at their doorsteps!