Industry 4.0: Turning Innovation into Value

Overview

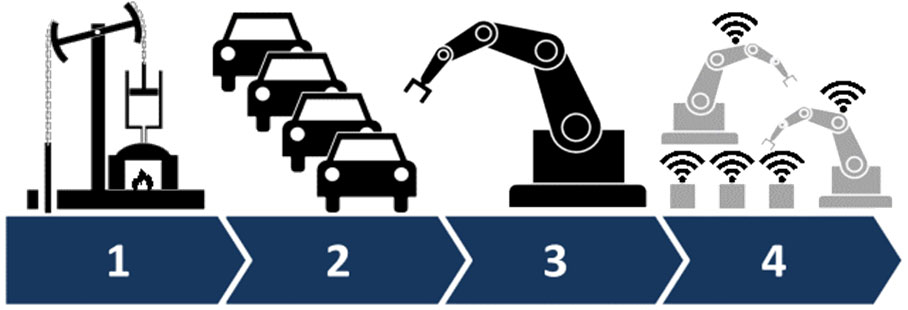

The first machines, powered by steam mechanized some of the work our ancestors did. Next was electricity, the assembly line and the birth of mass production. The advent of computers and the beginnings of automation, when robots and machines began to replace human workers on those assembly lines are the highlights of the third era of industry. From smartphones to smart fridges, technology has played a major role in advancing most areas of our everyday lives – but it is also transforming the world of industry.

The rise of new digital industrial technology, known as Industry 4.0, is a transformation that makes it possible to gather and analyse data across machines, enabling faster, more flexible, and more efficient processes to produce higher-quality goods at reduced costs. It incorporates cyber-physical systems, the Internet of things, cloud computing and cognitive computing.

Industry 4.0 fosters what has been called a “smart factory”. Within modular structured smart factories, cyber-physical systems monitor physical processes, create a virtual copy of the physical world and make decentralized decisions.

If a factory is producing a quality product, the processes are tuned, the supplier channel is correctly monitored and everything is running like a well-oiled machine. This goes back to the point about Industry 4.0 being more about optimization than invention. So, the answer on a case-by-case basis seems to be, “Not much.” That’s because the biggest difference between the dumb factories of today and the smart factories of tomorrow isn’t what’s inside them, but rather the network that connects them. As an analogy, consider the difference between having a home computer and having one connected to the Internet: even if the machines have identical hardware, the latter is obviously far more powerful.

For a factory or system to be considered Industry 4.0, it must include:

- Interoperability — machines, devices, sensors and people that connect and communicate with one another.

- Information transparency — the systems create a virtual copy of the physical world through sensor data in order to contextualize information.

- Use cases showing how our customers are gaining competitive advantage today by leveraging digital technologies.

- Technical assistance — both the ability of the systems to support humans in making decisions and solving problems and the ability to assist humans with tasks that are too difficult or unsafe for humans.

- Decentralized decision-making — the ability of cyber-physical systems to make simple decisions on their own and become as autonomous as possible

Industry 4.0 in Packaging:

Adopting Industry 4.0 into your packaging line can bring many benefits from better data management to improved efficiency. But while the benefits may be clear, replacing a complete production line may not be an option for packaging companies operating on already tight margins. While moving to a modern, flexible and smart line brings the most benefits, even small changes to existing facilities can deliver significant boosts to efficiency.

Smarter decision making:

By having the data available in a common and easy-to-understand format, operators and production controllers can make more informed decisions about the status of a packaging line. Issues can be identified more quickly and fixed faster. More importantly, smart systems can even detect potential issues before they occur, allowing preventive maintenance to be scheduled to ensure the line stay running.

Liked this article? Share it on:

Featured insights and blogs

The secret to cultivating operational excellence

A big focus area across industries is continuous improvement. Companies are under extreme pressure to perform but operational complexities hinder from realising intended outcome.

Make your factory smart for higher profitability

The smart factory is the factory of the future. It is one where processes are automated, interconnected, and continually reacting towards improving production systems and processes. In simple terms, it is ‘intelligent manufacturing.’

6 key benefits of industry 4.0

Industry 4.0 is the transformation of traditional industrial and manufacturing platforms into automated and interconnected systems capable of continuous autonomous improvement and automation.

Adopting cobots - Collaborative robots

The use of collaborative robots (cobots), is expected to grow at astonishing rates in the next few years. They have been a game-changer in the past decade due to their ability to work side-by-side with humans.

Our experts are always available to answer all your questions. Feel free to write to us and get your queries answered.

About Labh Group

Labh Group is a leading engineering, technology, consulting and manufacturing conglomerate, working closely with diversified industries spanning across food processing, agriculture, plastics, chemicals, healthcare, packaging and other industries and business sectors offering complete turn-key solutions including advanced engineering, Industry 4.0 solutions, expert technical and management consultancy and Digital Transformation. From the most demanding to the most distant customers across the globe, we empower them for rewriting their future with our depths of knowledge, unique ideas, technical expertise, creative solutions and enduring results, all at the most optimal costs, right at their doorsteps!

What we offer

Labh Group offers industry 4.0 enabled complete turnkey solutions to a wide range of industries. Click on the links to check out our solutions for packaging industry, food processing industry, chemicals industry, pharmaceutical industry, metals processing industry and many more.

We offer customized industrial products and raw materials for many diverse industries.

Our offerings also include a wide range of consumer products and daily household goods.