Packaging Machines Division

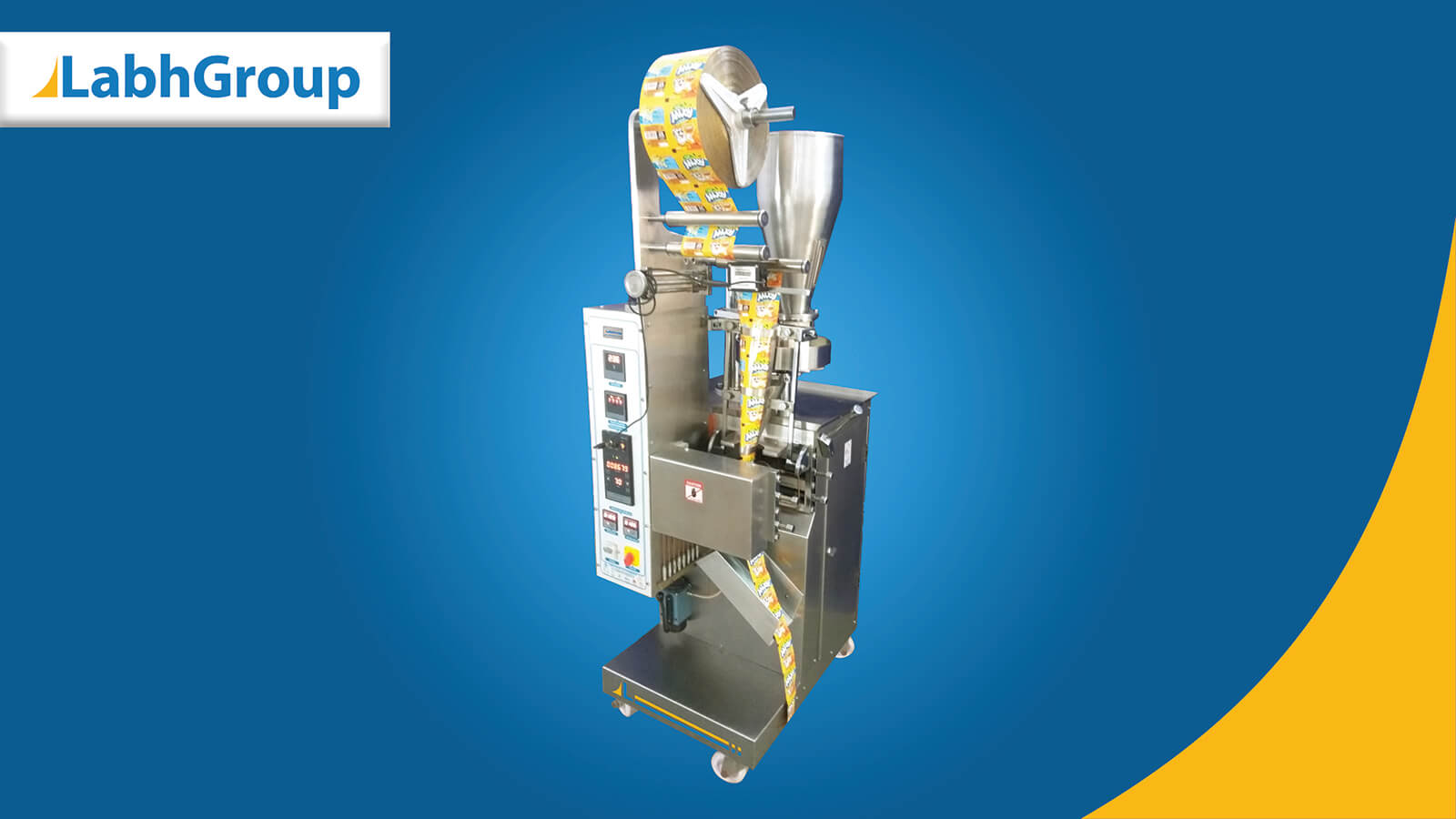

Automatic servo pouch packing machine with combinational weigh filler

Elite – Standard LA-455

Key Points

- Suitable to pack Sugar, Salt, Tea and similar products

- Speed : Up to 3000 Packs / Hour

- Pouch Width : 300 mm maximum

- Pouch Length : 450 mm maximum

- With advanced touch screen control

- Complete stainless steel design

How it Works ?

Know working of Automatic servo pouch packing machine with combinational weigh filler

It is fully automatic vertical form, fill and seal pouch packing machine. Printed packing material is in roll form. Machine former will form the pouch from the roll. Combinational weigh filler will decide exact quantity to be filled. Vertical and horizontal sealing will be done by heat sealer. Sealing temperature is controlled by digital temperature controller. Digital counter will display no. of pouches produced by machine which can be reset as per need. Machine can be supplied with in-feed conveyor, out-feed conveyor, data and online batch printing machine as an option.

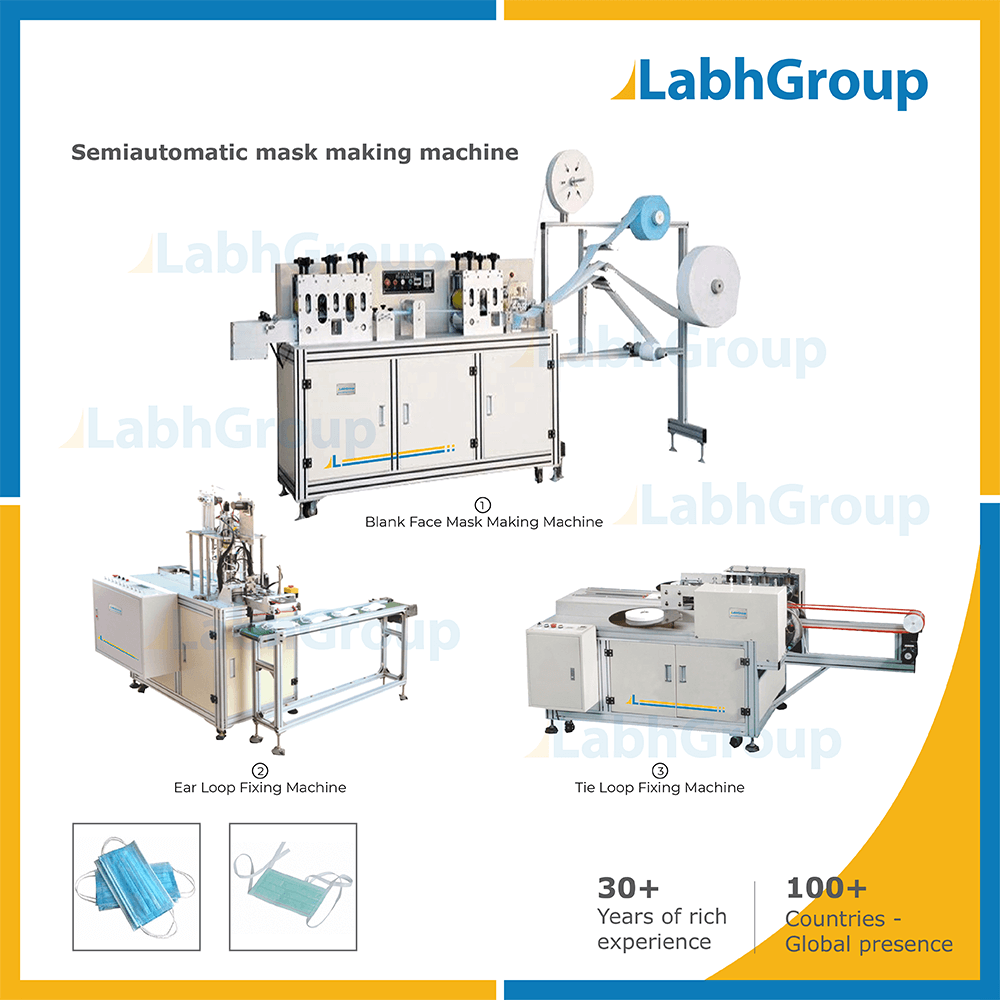

List of Machines

List of Machines for automatic servo pouch packing machine with combinational weigh filler

1 | Blank Face Mask Making Machine | To make mask blank from nonwoven material roll |

2 | Ear Loop Fixing Machine | To weld loop on blank mask |

3 | Tie Loop Fixing Machine | To weld tie loop on blank mask |

Technical Specifications

Important specifications of automatic servo pouch packing machine with combinational weigh filler

Name | Semi-automatic face mask making machine |

Product Category | Healthcare equipment |

Product Group | Healthcare technology |

Material | Nonwoven material |

Material GSM | Up to 30 GSM |

Speed | Up to 70 masks per minute |

Mask Length | Up to 175 mm |

Mask Width | Up to 100 mm |

Melting Technique | Ultrasonic melting |

Outstanding features

Important features of automatic servo pouch packing machine with combinational weigh filler

Ease of operation

Intuitive control processes and a large color touch screen with easily identifiable graphics assure user-friendly operation for reliable and efficient production. Industrial PC includes a full color touch screen, easy to understand graphics, that allows the operator to easily adjust machine parameters, and adaptation into your local language.

Labh IOT

Now control everything from any corner of the world for complete peace of mind. Get the real time information about working of the machine, production, breakdown and take instant action for maximum productivity.

Ease of operation

Intuitive control processes and a large color touch screen with easily identifiable graphics assure user-friendly operation for reliable and efficient production. Industrial PC includes a full color touch screen, easy to understand graphics, that allows the operator to easily adjust machine parameters, and adaptation into your local language.

Labh IOT

Now control everything from any corner of the world for complete peace of mind. Get the real time information about working of the machine, production, breakdown and take instant action for maximum productivity.

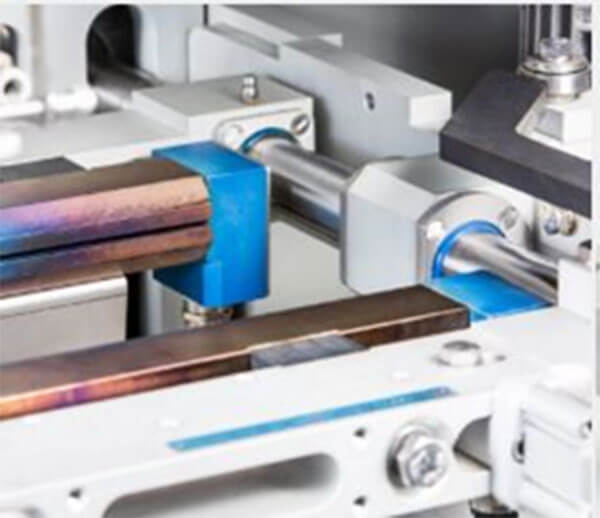

Latest design robust sealing mechanism

Advance design of sealer ensure perfect sealing for long-life of sachets on the shelf

Other Features

Salient features of automatic servo pouch packing machine with combinational weigh filler

- Adopt advanced PLC control with touch screen control panel for perfect tuning of machine operation

- With servo motor control for high efficiency and great precision

- Require single phase power supply only

- Very low maintenance and operating cost

- With advance combinational filler system for accurate filling of product

- Specially designed one-piece former for easy and fast change over

- With digital temperature control system for perfect sealing

- With digital counter to count number of pouches produced by the machine

- All product contact parts are made up of Stainless Steel

- Sturdy design to ensure long life and trouble-free operation

- Complete Stainless-Steel covering

Bought out Items

- Batch printing device : To print manufacturing date, batch no. etc. on the pouches

- Nitrogen flushing device : To flush the pouch and add nitrogen at the time of filling for the long shelf life

- Static charge eliminator : To remove static charge from the packaging film before filling of the product

Optional Items

- Batch printing device : To print manufacturing date, batch no. etc. on the pouches

- Nitrogen flushing device : To flush the pouch and add nitrogen at the time of filling for the long shelf life

- Static charge eliminator : To remove static charge from the packaging film before filling of the product

Ancillary Items

- In-feed Conveyor : To convey products from ground level to machine hopper

- Out-feed Conveyor : To convey pouches from ground to the table height

- Online Check Weigher : To check for the desired weight and reject improper pouches

- Online Metal Detector : To detect pouches with any metal content in it

Know more about us

Labh Ability

Our unique scope of providing next-generation start to end turnkey solutions

Advantage Labh Group

Why thousands of companies from all around the world, from start-up to multinationals keep choosing Labh Group for all their needs.

About Division

Know in details about our snacks food processing machine division and how can we help to your industry.

About Labh Group

Know more about our group. Who we are and what we do and why we do what we do!

Labhopedia

An ocean of information to keep you updated with latest technology and trend in your industry to keep you ahead of your competitors, always!

Social media

There is always something happening at Labh Group. It is good to be connected and stay informed.

Testimonials

Hear directly from our customers!

Mahmud Khan

Anthony Fernando

Associating with Labh Group has proved to be very beneficial for my company. From installing machines to developing promotional strategies, they have always provided us with the most innovative solutions for all our needs.

Artur Gushchevarov

Emanuel Daniel

Choosing Labh Group as our turn-key solutions provider, we successfully completed the project very quickly, saved cost and accomplished everything without any stress.

Jim Edwards

Thanks to Labh Group, I no longer need to worry about my plant. WIth Labh IoT, I can monitor my entire production line with a single tap

Eric Sandler

With InstaStart, I got the freedom to explore products in different industries and find the most profitable market. This helped me reduce my risk and take proper well-informed decision before making heavy in plants and machineries.

Kingsley Dsouza

Alan Zabirova

Labh Group provided me with the best technology at a very reasonable price. Because of this I was able to invest more in promoting my product which helped me gain significant market share in a short period of time.

Related Products

Ask our Experts

Send Inquiry

- Popular Tags :

- PSA Medical Oxygen generation Plant

- Industry 4.0 solutions

- LaBot - Labh Robot

- LaDro - Labh Drones

- Project consultancy

- LabhERP

- Technical Consultancy

- Big data solutions

- Labh SmallStart

- Labh InstaStart

- Global presence

- Advantage Labh Group

- Next-gen turn-key solutions

- Labh Mantra

- Life @ Labh Group

- Women empowerment @ Labh Group