What we do

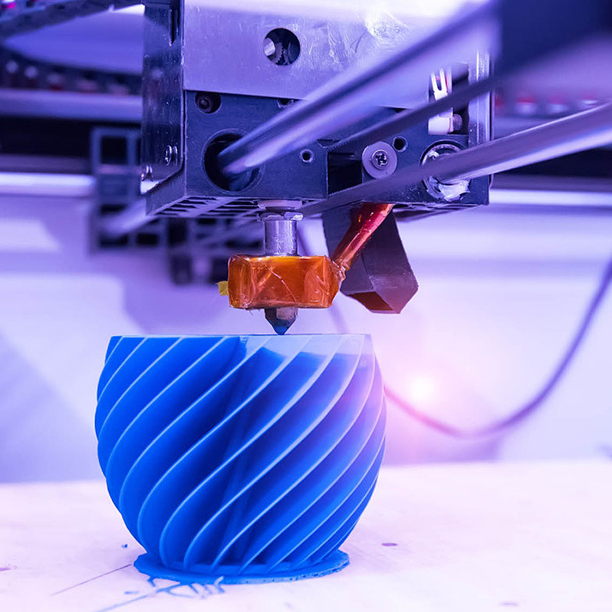

3D printing

Building reality one layer at a time

Additive manufacturing

Additive manufacturing or 3D printing is a manufacturing methodology that encompasses a range of processes and applications, with a common theme of building parts up, usually layer-upon-layer. This additive approach ultimately enables manufacturers to eliminate the need for tooling. A 3D printed part significantly reduces waste which is otherwise generated in machining.

You can create complex designs that would be impossible to make otherwise that too in a much shorter time. Traditionally used only for prototyping and tooling, 3D printing now has a big impact on the packaging industry and many other related industries.

Benefits of 3D printing

Creating prototypes

Rapid prototyping is a critical use case of 3D printing for the industrial goods sector. Design changes that would have taken months using conventional manufacturing methods can be implemented much faster, often in under a week, using 3D printing.

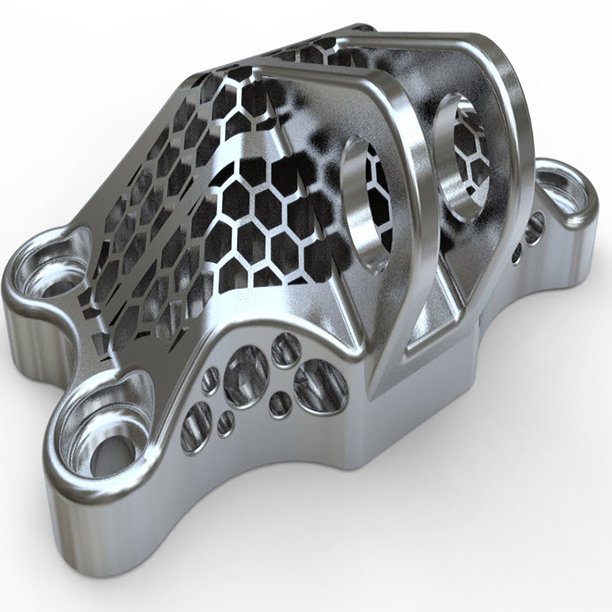

Producing complex designs

3D printing is a cost-effective technology for producing parts with complex geometries. Designs that would otherwise be impossible to produce with conventional manufacturing can now be produced with 3D printing.

On-demand production

3D printing can produce physical parts from digital files in a matter of hours, instead of stocking spare parts, companies can leverage a new model of manufacturing these parts on demand at the point of need thus reducing inventory, and cost of storage of parts that have low demand.

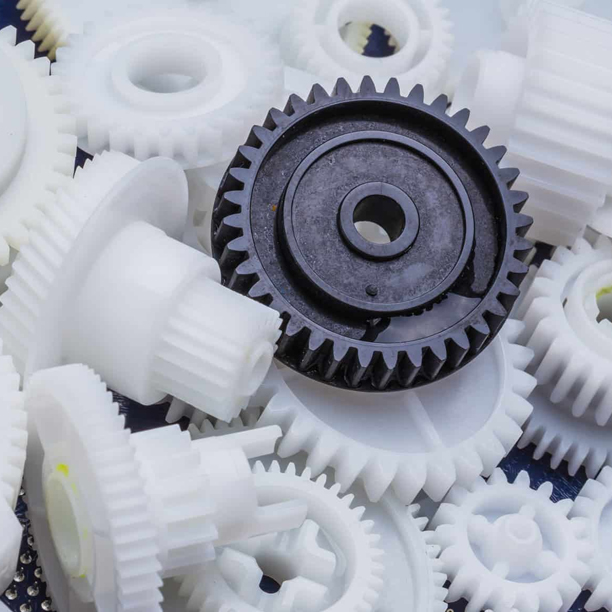

Strong and lightweight parts

The main 3D printing material used is plastic, although some metals can also be used for 3D printing. However, plastics offer advantages as they are lighter than their metal equivalents. Parts can also be created from tailored materials to provide specific properties such as heat resistance, higher strength or water repellency.

Ask our Experts

Send Inquiry

Digital Transformation

What We Do

Big Data

What We Do

- Popular Tags :

- PSA Medical Oxygen generation Plant

- Industry 4.0 solutions

- LaBot - Labh Robot

- LaDro - Labh Drones

- Project consultancy

- LabhERP

- Technical Consultancy

- Big data solutions

- Labh SmallStart

- Labh InstaStart

- Global presence

- Advantage Labh Group

- Next-gen turn-key solutions

- Labh Mantra

- Life @ Labh Group

- Women empowerment @ Labh Group